Products

Hyprolyser

Sodium Hypochlorite Generation

- Convert from chemical deliveries to salt deliveries

- 0.6% hypochlorite generation from 3g/hr/to 5000g/hr (240kg chlorine/day)

- Fully automatic plant that is easily integrated to any existing disinfection plant

- Remote monitored

- Remove OHS management typically associated with the use of hazardous materials/ dangerous goods

Portable Dosing Unit - PDU

Chemical dosing of systems, mains and storages

- Fully automatic or manual operation

- Instrumentation for system monitoring

- Fully bunded and contained

- Low and high-capacity dosing pumps

- On-board generator

- Sample water return system

- Safety signage

- LED lighting

- Eyewash station

- Chemical spill kit

Download a Brochure

Hyprolyser Hut

Chemical dosing of mains and storages

- 0.6% Hypo generation from 5L/hr to 60L/hr

- Onboard storage up to 1000L with ability to augment additional storage capacity

- Fully automatic plant

- Remote monitoring

- Instrumentation for system monitoring

- Up to 3 analyser systems

- Low and high-capacity dosing pumps

- Automatic Transfer Switch and local Generator

- Sample water return system

- Safety Signage

- LED Lighting

Download a Brochure

Compact Dosing Unit - CDU

Simple, easy dosing all in one small box

- Easy to handle box, measuring approximately 400 x 400 x 500mm.

- Onboard storage up to 15L using quick drop in carboy

- Single GRUNDFOSS DDA Dosing Pump, with pressure control all manually operable.

- 5l/h @ 16bar to 60l/h @ 10bar

- Container fully constructed from HDPE

- Super-quick, easy deployment

- 240Vac (can be sold with 12Vdc/ 240Vac inverter)

- Weighs 17kg (Dry)

- Dosing connections provided to suit your application.

Pre-cast Concrete Dosing Unit - PCDU

Chemical dosing of systems, mains or storages

- Fully automatic or manual operation

- Remote and full local monitoring

- Instrumentation for system monitoring

- Fully bunded and contained system

- Up to 2500 litre storage capacity

- Low and high-capacity dosing pumps arranged in duty/standby configuration

- Carrier water or direct chemical injection

- Safety signage

- LED lighting

- Shower/Eyewash station

- Chemical spill kit

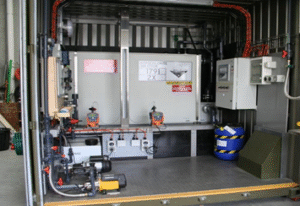

Transportable Dosing Unit - TDU

An on-site configurable, transportable disinfection plant

- onsite configurable via HMI, no programming changes required

- Fully automatic or manual operation

- Instrumentation for system monitoring

- Fully bunded and contained

- Low and high-capacity dosing pumps

- On-board generator

- Sample water return system

- RCD protected

- Safety signage

- LED lighting

- Eyewash station

- Chemical spill kit

Download a Brochure

M-Dose

De-chlorination made easy

- An easy-to-handle system that can be used on sites.

- Can treat (flow pace dose) from 5 L/min to 600L/min.

- Single GRUNDFOSS DDI Dosing Pump, with pressure control, flow paced dosing or manually operable.

- Super-quick, easy deployment

- Battery operated

- Weighs 40kg. (dry)

Chlorine On-line Telemetry Unit

Chlorine residual monitoring made easy

- Stand-alone cabinet or wall mounted system

- Measurement of Chlorine Residual, pH, Turbidity, Temperature; …. any measurement that may be possible in a water/ wastewater application.

- 24Vdc backup for continuous monitoring

- Designed to your preferred equipment requirements

- Sample Water Return System (optional)

Chlorine Residual Trim Unit - CRTU

A self-contained, fully functional chemical dosing plant

- Chemical dosing of systems, mains or storages

- Fully automatic or manually operable

- PLC or Analyser based control

- Remote monitoring

- Duty/Standby dosing pumps

- Instrumentation for local and remote monitoring of system

- Fully bunded and contained system

- Safety Signage

- LED Lighting

- Sample water return system (up to 10 bar)

- Booster pump system

- pH measurement

We are Water Industry Experts!

Years in operation

0

+

Successful projects

0

+

Satisfaction rate

0

%

Need Help?

Choose Jonoco for your next project!

Contact Us

Call us on (03) 9540 0311 or fill out the contact form below with your enquiry.